Overview

PMI Based inspection

PMI in the computer-aided design stands for Product Manufacturing Information. PMI is non-geometric data included within a 3D CAD file. Rather than relying on 2D drawings or digital documents to convey engineering or manufacturing data, it can all be embedded within the original CAD file. The attributes include Geometric Dimensions and Tolerances (GD&T), 3D annotation dimensions, and surface finishes. The manufacturing 3D inspection software includes features like pockets, slots, surfaces, and holes. So PMI is meant to convey information, or translate, from the CAD model to the Manufacturing. PMI eliminates the need for 2D drawings by creating manufacturing information directly on the 3D model. The direct import and evaluation of PMI data including tolerance specifications from 3D design models accelerate new product developments and production processes by 3D measurement planning on the CAD data set.

WORKFLOW

Open Software.png)

Open Software

Click on Menu Tab.png)

Click on Menu Tab

select PMI Step.png)

Select PMI Step

Shows all PMI Information.png)

Shows all PMI Information

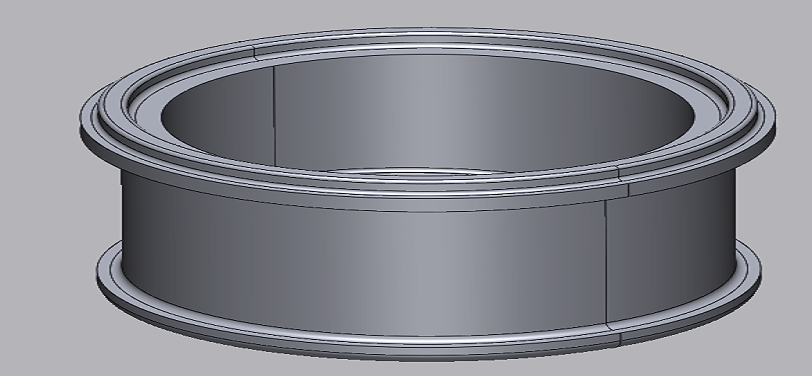

IMAGE

VIDEO

INDUSTRIES WE SERVE

WHAT'S NEXT?

RELATED BLOGS

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more