PROCESS AND METHODOLOGY

VEHICLE SCAN

VEHICLE EXTERIOR In this step we scan complete exterior of the vehicle (Top, Underbody, Front & Rear)

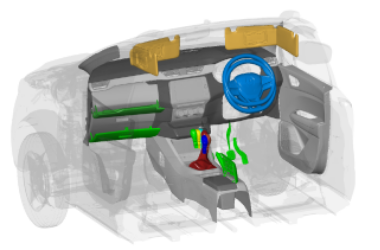

VEHICLE INTERIOR In this step we scan Interior of the completed vehicle (IP, Rear Compartment ,Floor, Pillars)

VEHICLE ADDITIONAL SCAN

In exterior additional scans, we do (doors in two or three opening positions, from closed positions, wiper sweeping area, black ceramics & dotted area, fuel opened position).

In interior additional scans we do (seat tracking, seat positions, gear positions, steering positions, handbrake positions, glove box opened, sun visor positions, armrest position, sunglass holder position).

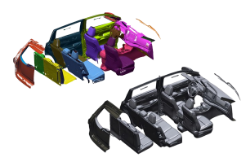

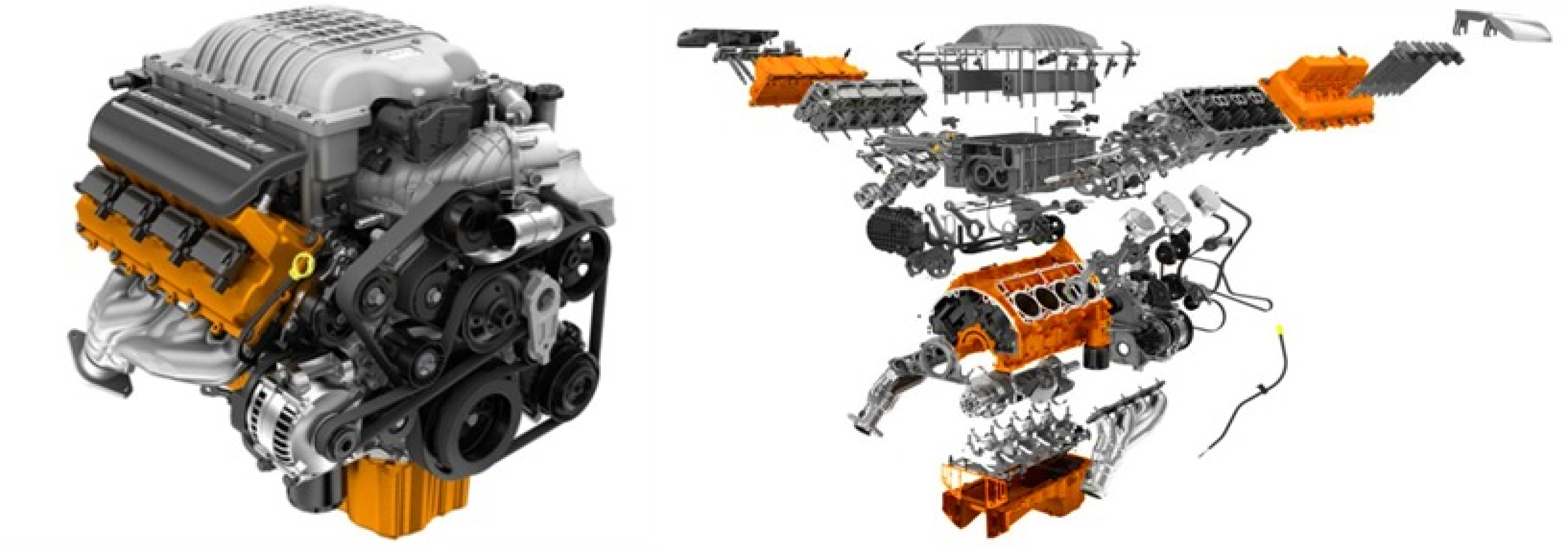

VEHICLE SYSTEM LEVEL SCAN

In vehicle system level-vehicle will torn down to part level and all the Individual part will get scan in this process

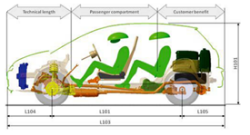

ERGONOMICS STUDY

In this step we find the Driver Seating position (H-Point) & Seat travel for the vehicle according to SAEJ826 method . Also seating position for 2nd row seat & 3rd row seat with respective to the driving position .

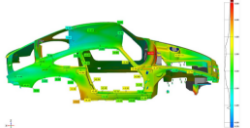

Alignment & Post processing

All the scanned data are post processed & aligned to their exact position of the vehicle coordinates.