PROCESS AND METHODOLOGY

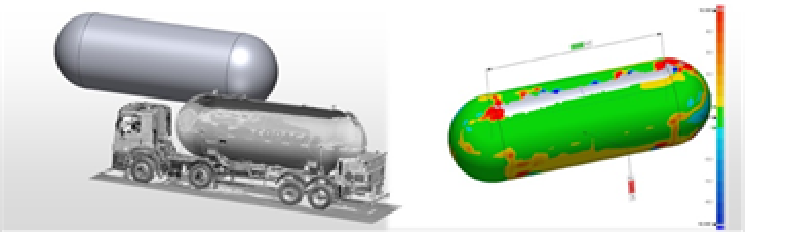

3D Scan

In this step we scan the part or vehicle which need to do get inspect.

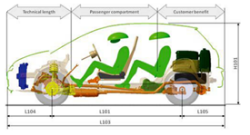

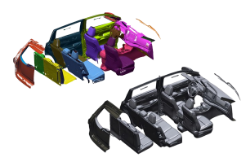

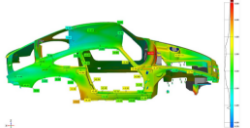

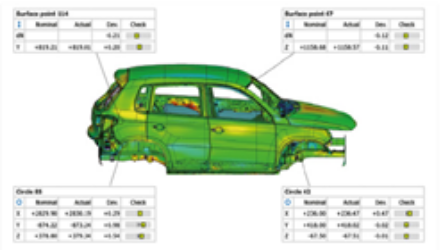

3D Inspection

In this step we inspect the Part, System or Vehicle, based on the customer’s scope of work

Report Creation

In this step we create the report for the inspected part/system or vehicle in detail.