PROCESS AND METHODOLOGY

VEHICLE ASPECTS

Overview Picture of Vehicle Exterior & Interior, Infotainment system & cluster information, Suspensions & special features analysis, Gap and Flush Analysis, Physical Measurement LWH of the vehicle, Effort measurements etc

Global Vehicle photographs

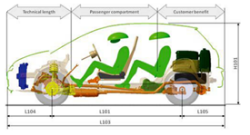

Vehicle Physical Measurements

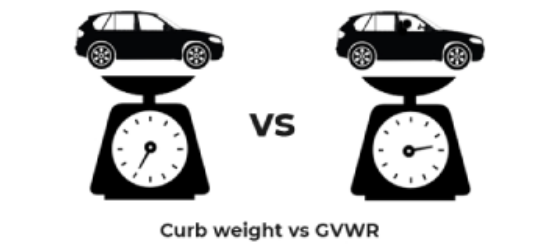

WEIGHT ANALYSIS

These are nothing but Finding the front and rear axle load difference weights of an Vehicle at two different conditions.

1. Curb Weight

2. GVMR

TEARDOWN

Physical teardown process happen here, where dismantling and data's capturing the complete vehicle in different levels also Consumable Extraction happen.

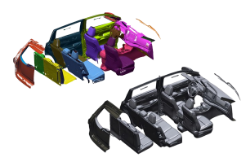

Teardown Level 1-System Level

Teardown Level 2-Part Level

Level 1 - System-wise-Engine, Bumper, Heating System, etc…will torn down and capture the data’s (Photos, Weight, Measurement's etc..)

Level 2 - Component wise-Engine parts, Bumper Parts, Heating System Parts… etc, Level 1 systems will further dismantle in to components level capture the data’s (Photos, Weight, Measurement's, Material details, Manufacture Details, Fastener Sequence, etc..)

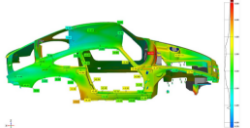

DATA MAPPING

All the Data analyzed and captured in Aspects, Teardown Process levels are mapped together in one unique platform with all information of the vehicle from the initial analysis to the final teardown deliverables listed.