Scan to cad services

Online Digital Reverse Engineering Service

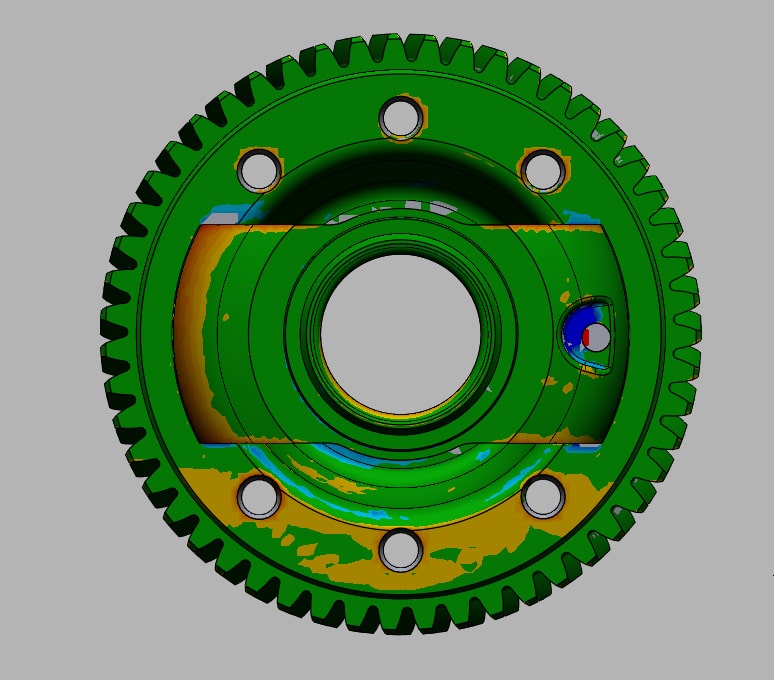

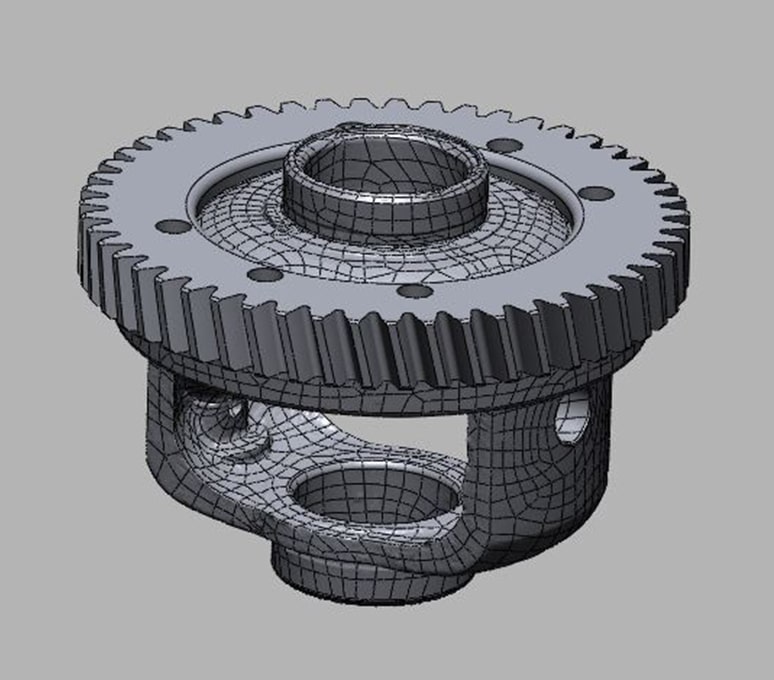

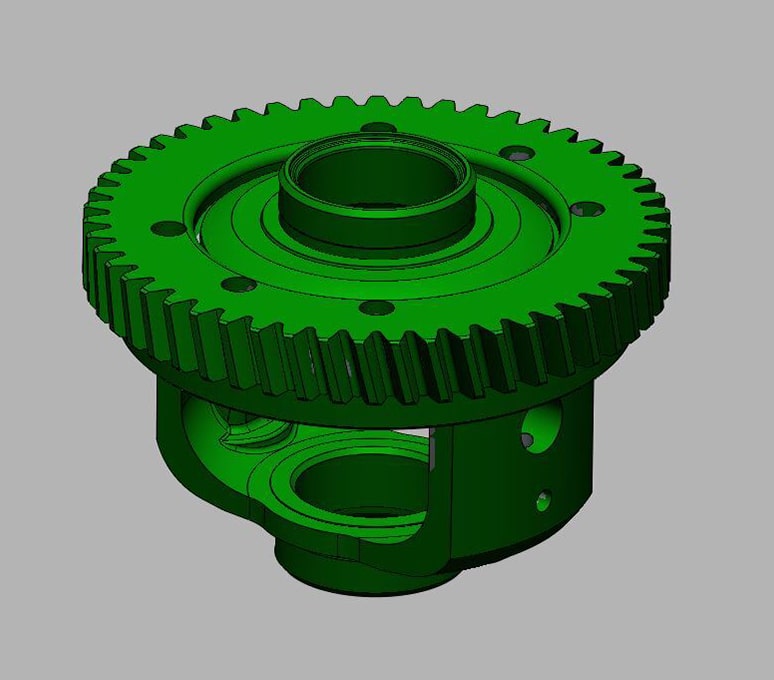

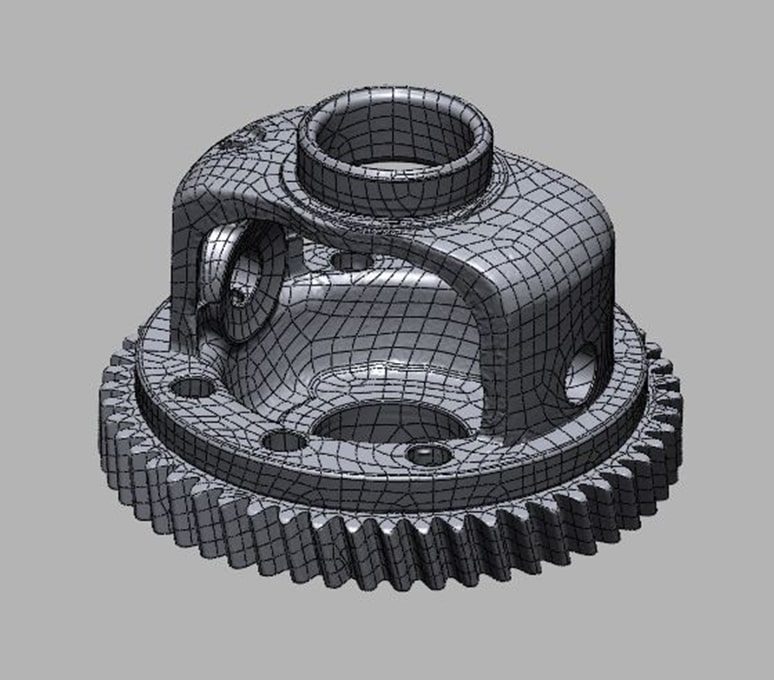

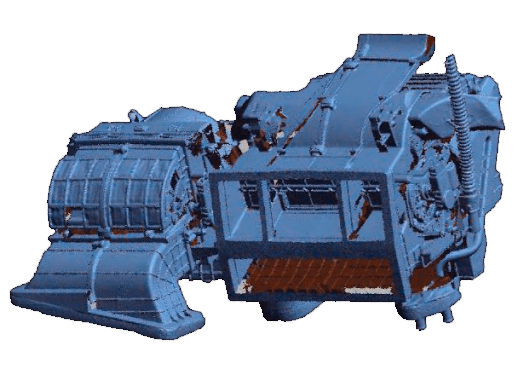

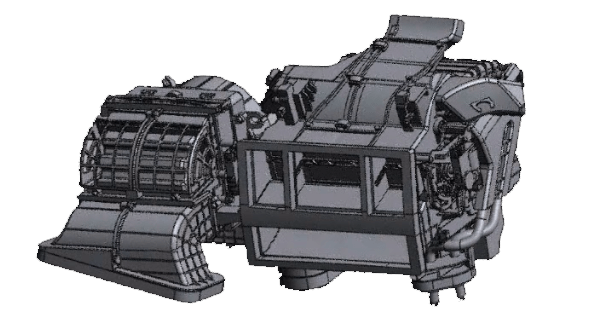

SCAN DATA

CAD DATA

Get your 3D Scans Converted into CAD files

More than 50 + Digital applications in one online platform

- Any Large volume projects can be executed

- Before you do it in-house try us once

- Save on average 35% off your Scan to CAD project Cost.

Precise3DM Digital Reverse Engineering service helps customers to convert the complicated 3D Scan into CAD files that are editable, ready to manufacture, analyze, or be used for any other downstream applications. Utilize our team of highly skilled reverse engineers using cutting-edge software. Get cost-effective, per-part pricing instantly. Once you approve, our team will immediately get in touch with you and process your 3D Scan to CAD.

India's largest team dedicated to Digital Reverse Engineering using professional software for Reverse Engineering

India's largest team dedicated to Digital Reverse Engineering using professional software for Reverse Engineering