Vehicle & scanner setup

- Ensuring the vehicle with all recommended fluids, tire pressure at proper level & proper fixation of parts

- Making a global reference point for scanning to reduce error and increase more accuracy photogrammetry is used

- Before starting a project scanner is always calibrated.

Deformation Analysis

- Scanning the vehicle at variable weight conditions like a curb, GVWR to analyze how much the vehicle is lowered in variable weight conditions

- Curb Plane: The vehicle is filled with all consumables at the correct level but no passengers and cargo

- GVWR: Vehicle is filled with all consumables at correct level & loaded with passengers and cargo

3D Optical

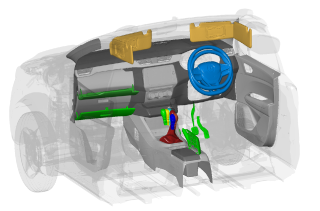

- In 3D optical the entire vehicle is scanned in detail like the front bumper, underbody with aero shield, underbody without aero shield, LH side, RH side, top side, rear bumper, doors, engine compartment, seats, instrument panel, top filler, interior trims, trunk compartment, wheels, turning radius. After complete scanning, a global car file is created by aligning all the files in single files using photogrammetry points

Additional scans

- In cars, we have a DOF part in both interior & exterior in that we have scanned some of the parts in that variable conditions for analysis purpose

- In exterior additional scans, we do(doors in two or three opening positions, from closed positions, wiper sweeping area, black ceramics & dotted area, fuel opened position )

- In interior additional scans we do (seat tracking, seat positions, gear positions, steering positions, handbrake positions, glove box opened, sun visor positions, armrest position, sunglass holder position)

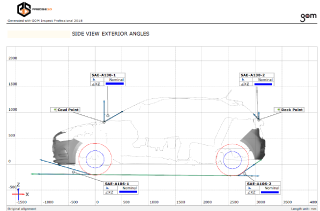

Ergonomics study

- For the ergonomic study of the vehicle, we used manikin to measure the details.

- Manikin is placed and measured according to SAEj826 standards for ergonomics study and interior measurements

- We placed the manikin in all the rows in the car at variable positions depends upon the seat type in that car and it is scanned and further, it is used for value analysis