Comparative & Feature Analysis

- Detailed comparison analysis of two or more vehicles with Engine power, suspension type, gearbox model, safety features, consumables, no of assemblies, total no of parts, materials usages percentage, weight comparison, etc

Data Analytics

- Detailed analysis of vehicle body structure, built type, gear ratio, engine power details, suspension details, safety features, cooling system, consumables usage, individual assembly system weight details, Biw structure details.

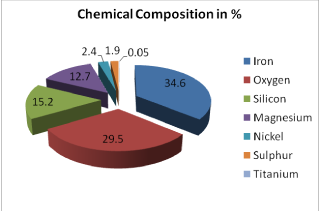

Chemical Compositions

- Chemical analysis of metals can identify and quantify the elemental composition of the material and help support your quality control process and material cost analytics.

Idea generation

- Based on the comparative & feature analysis and data analytics report will be generated on cost saving ideas in manufacturing process, material usage, design optimization and product development