PROCESS AND METHODOLOGY

DETAILS OF WIRES

Belongs to which wiring harness

Connected parts

Wire section diameter (with & without sleeve)

Pin material

Insulation details on wire

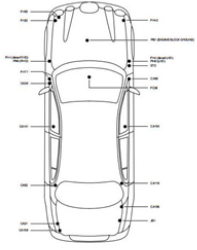

DETAILS OF BODY GROUND POINTS

Manufacturer (if present)

Material

Cavities in connector

Pin count in connector

Reference no

Color

Location

Connector type

DETAILS OF BODY GROUND POINTS

Number of body grounded points

Location of earth points

Fastener details.

SCHEMATICS

Schematics of all wiring Harness as separate files

Schematic of grounds

Schematics of control units, fuses & relay locations

Schematics of CAN systems

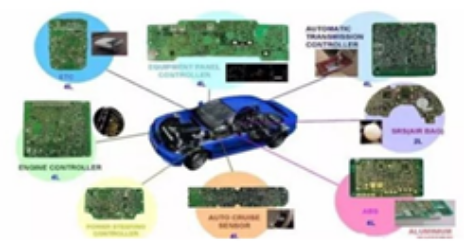

Electronics

Electronic Benchmarking is a key for complexity management of vehicle electronics components ,where analysis report include Engine Electronics, Transmission Electronics, Chassis Electronics, Passive Safety, Driver Assistance, Passenger Comfort, Entertainment Systems, Electronic, and Integrated Cockpit System