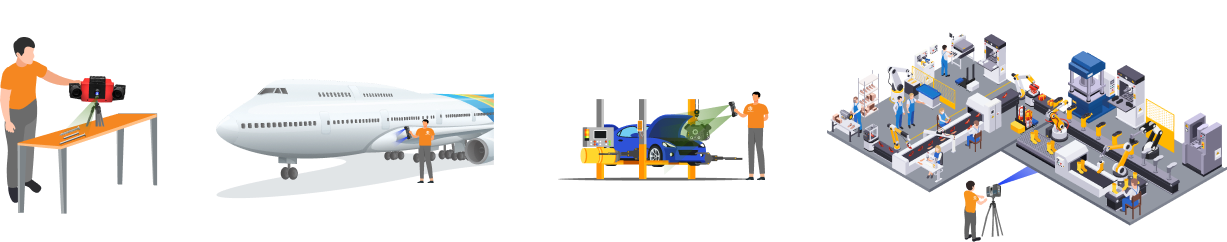

Tailored Selection

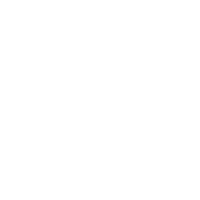

Based on your information, we will identify the ideal 3D Scanner

and

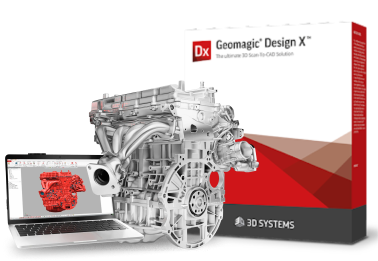

Geomagic software bundle

that

aligns with

your budget and application needs.