Overview

First Article Inspection

In the manufacturing industry, the dimension of the parts is critical, and it raises issues in the production process. There are many types of inspection but if we want to catch the issues earlier, we can go for First Article Inspection or FAI. A First Article Inspection (FAI) is a design verification and design history file and a formal method of providing a reported measurement for each manufactured feature of a part or assembly. FAI verifies the production process in every parameter, rather than just concentrating on “critical” dimensions. Even the smallest deviation from an original design can be detected and quickly corrected using FAI. Usually, First Article Inspection could take half a day to set up and hours to run. By using a 3D scanner and 3D inspection Geomagic Control X software, the process merely takes only a few minutes and adds flexibility to design changes. The CAD model and the point cloud are automatically aligned within Geomagic Control X software. It depicts color map deviations and provides graphical comparisons for dimensions, datums, features and other quality factors. Geomagic Control X will bring data from the inspection library to develop a finished inspection report. The report is given to the customer in the PDF format. First article inspection is associated with specific industries like aerospace and defense, automotive, electrical and electronics, and medical device industries.

WORKFLOW

Import Cad file.png)

Import CAD file

Import 3D scan file.png)

Import 3D scan file

Initial alignment.png)

Initial alignment

bestfit alignment.png)

Bestfit alignment

Surface Comparison.png)

Surface Comparison

Measuring 3D dimensions from 2d drawing.png)

Measuring 3D dimensions from 2D drawing

Taking some other dimensions.png)

Taking some other dimensions

Measuring 2d dimensions.png)

Measuring 2D dimensions

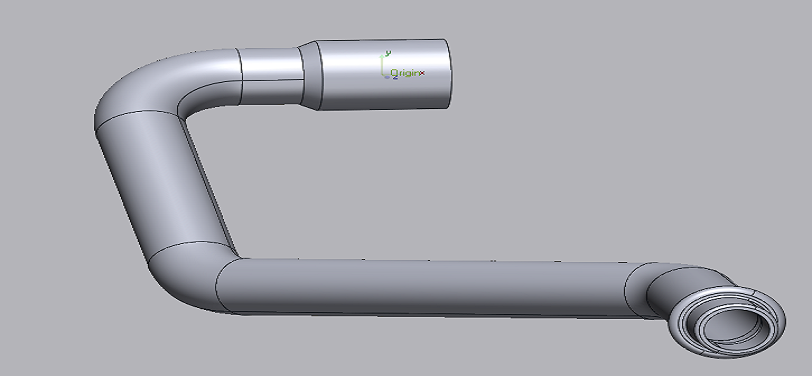

IMAGE

VIDEO

INDUSTRIES WE SERVE

WHAT'S NEXT?

RELATED BLOGS

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more