Overview

Digital gap and flush measurement

Digital Gap and Flush measurement offer a wide range of innovative and robust solutions like reduce wind noise concerns, improve overall body fit-and-finish, increase effectiveness, and specifically designed to help manufacturers optimize build quality. This feature is developed by 3D inspection software. It can quickly and accurately inspect direct dimensions using CAD surfaces, depending on the surface normal during the measurement. This method is extensively used in the automotive and aerospace industries.Curves functionality feature for flush and gap measurement closes the gap between point-based and surface-based inspection. Full-field digitized data is used to apply construction functions for curves and to visualize their individual properties. Edge curves can be captured, radii and character lines analyzed and spline curves created. Flush & gap analysis is another element provided in the curve-based inspection.

WORKFLOW

Import Cad and Scan File and do alignment.png)

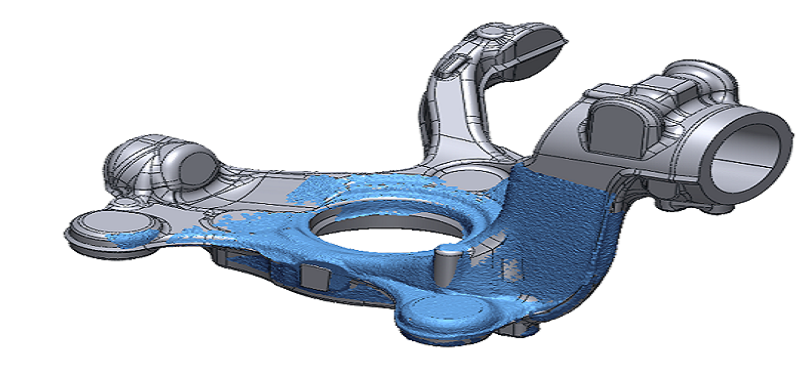

Import CAD and Scan File and do alignment

checking of gap at different posistions.png)

Checking of gap at different posistions

IMAGE

VIDEO

INDUSTRIES WE SERVE

WHAT'S NEXT?

RELATED BLOGS

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more